AVEVA’S new channel strategy, combining digital and sustainability

BY ARUN SHANKAR

Digital transformation has impacted all business and industries, with varying degree of adoption and pace. While traditional IT enterprise applications have been migrating to cloud-based, Software-as-a-Service and pay-as-you-go models for more than a decade, the pandemic has triggered interest in other software areas as well.

The industrial sector, in particular, has been slow to embrace the possibilities of digital transformation, often relying on piecemeal point solutions that reinforce organisational silos. AVEVA, a global vendor in sustainable digital transformation across the industrial sector, offers a digital-first platform approach that allows organisations to track sustainability targets at the same time.

AVEVA’s solutions are source-agnostic and interoperable in the cloud, and addresses multiple use cases supporting greener outcomes.

“Industrial enterprises are responding to the changed ways in which we do business in the new normal,” says Kerry Grimes, Head of Global Partners, AVEVA. “The rapid move to industrial digital transformation has been enhanced by the pandemic. Alongside, increasing stakeholder demand for greener and more sustainable outcomes forcing industrial organisations to rethink value chains. Embedding digital solutions at the heart of the industrial enterprise responds to both challenges.”

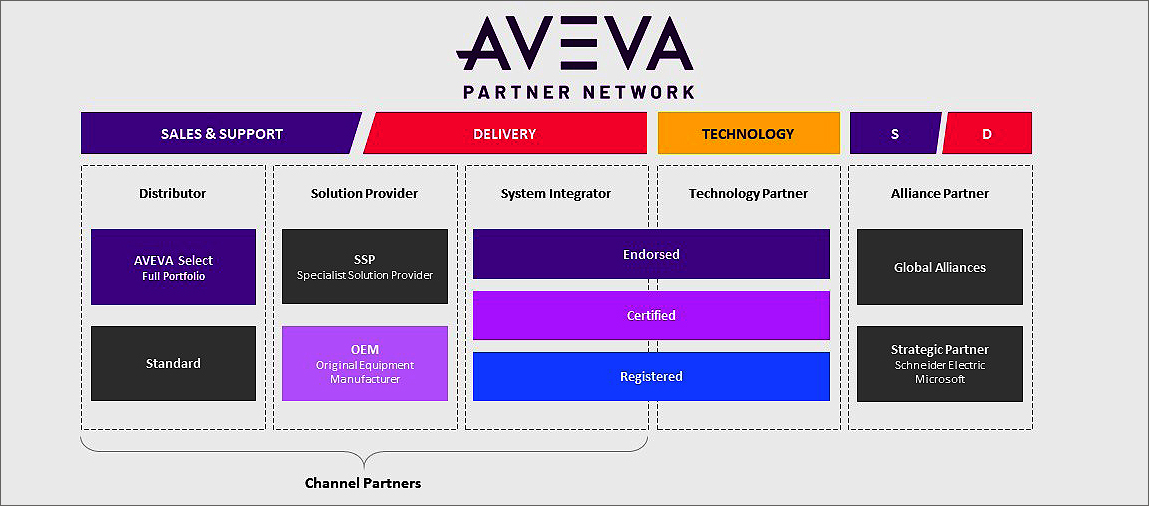

Grimes is a recognisable face to channel partners in his role as Head of AVEVA’s partner organisation, which comprises of strategic partners such as Schneider Electric and Microsoft, as well as technology and channel partners, including distributors, systems integrators, OEM partners and solutions providers.

Grimes is a recognisable face to channel partners in his role as Head of AVEVA’s partner organisation, which comprises of strategic partners such as Schneider Electric and Microsoft, as well as technology and channel partners, including distributors, systems integrators, OEM partners and solutions providers.

He offers a rundown of how the company’s products can leverage the benefits of digital transformation and sustainability for customers with a focus on Human Machine Interface, HMI and Supervisory Control and Data Acquisition, SCADA software.

Why did AVEVA acquire OSIsoft

Over the past year, AVEVA has doubled down its efforts to support industries in their digital transformation journeys with a suite of cloud, big data, AI and industrial IoT solutions. The British multinational has been unveiling new solutions and initiatives to drive engineering efficiency, operational excellence, resiliency and agility to help shape a digital sustainable future across the industrial sector.

In March this year, AVEVA acquired OSIsoft, a California-based manufacturer of real-time data management application software, to meet the needs of industrial companies and accelerate their digital transformation. The combined portfolio brings OSIsoft’s data management together with AVEVA’s industrial software to unlock what the company calls Performance Intelligence. The concept was developed by AVEVA to explain how the combination of industrial data management and software unlocks success in today’s operating environment.

Traditionally close to 90% of OSIsoft business has been sold direct

The recent acquisition of OSIsoft allows the AVEVA to lead in the Historian Big Data space and visualisation space, enhancing its monitoring control portfolio. By integrating OSIsoft’s intelligent tools into its industrial automation software portfolio, AVEVA now provides solutions that span edge, plant, and enterprise deployments.

OSIsoft’s Performance Intelligence connects information and artificial intelligence, to enable faster and accurate decision making, helping industries boost sustainability. By pairing the capabilities of OSIsoft’s PI System with AVEVA’S industrial software, Performance Intelligence gives people behind essential processes, reliable data to understand the industrial lifecycle.

Performance Intelligence provides operational agility for industries by connecting AI with human insight

Areas where Performance Intelligence is likely to have most impact include organisational productivity, operational agility, and sustainability.

Traditionally, close to 90% of OSIsoft business has been sold direct, indicates Grimes. “They have done some OEM agreements with industry automation vendors that I want to leverage and capitalise on, because it gives us a foot in the door,” Grimes expresses.

With OSIsoft, there is the opportunity for AVEVA to cross sell some of its control portfolio solutions into the industrial automation space.

The OSIsoft go to market model is mostly direct business, with only 10-15% of the business sold through OEM channels. OSIsoft has been using industry automation vendors as their distribution channel partners. The merger allows both sides to make use of their channel partner programmes.

And why is OSIsoft big for AVEVA

“It has been a great acquisition for us, not just in terms of technology, but how we can bring together the different pieces of our partner programme. We can now enable our channel to take OSI’s PI through, and we can leverage where their strength was with industry automation players, to promote our hardware agnostic software. As well as other pieces of the AVEVA portfolio as well,” says Grimes.

“We are now bringing together two leading fields of technologies,” says Grimes. “I believe the whole Performance Intelligence area is at its crossroads.”

AVEVA’s Asset Lifecycle products work horizontally, and include engineering, designing, operations, analysing, and maintaining the plant. Operations control and the HMI SCADA offering is positioned in the middle of the operations and asset management lifecycles and Historian process control.

Grimes feels Performance Intelligence is really big

“That is where we intersect operations control with the whole HMI SCADA platform,” adds Grimes. AVEVA expects Performance Intelligence to help customers manage plant assets as well as their production. Whatever type of production, Performance Intelligence is set up to deliver results.

Grimes feels Performance Intelligence is really big. Performance Intelligence provides greater operational agility and resilience for industries by connecting the power of information and AI with human insight.

By pairing the trusted capabilities of OSIsoft’s PI System with AVEVA’s software portfolio, the people managing essential processes benefit from rich data that allows them to visualise the entire industrial lifecycle. This empowers them to make faster and precise decisions and enables companies to boost sustainability performance.

AVEVA’s leased approach to software

Other than changing product architecture of operations and asset management lifecycle, AVEVA is also altering how systems, including HMI SCADA, are sold through the channel. IT industry software vendors have successfully moved their end customers from a perpetual licensing, capital purchase to a recurring operating purchase. This is making purchase and usage of software agile and flexible.

However, unlike IT industry, industrial software players like AVEVA struggle to make it work on the plant floor. And the reason is, industrial plants are built to work for ten years, without having to do anything more to keep them going. While all that is starting to change in the world of digital transformation, plant floor managers still have an aversion to subscriptions, points out Grimes.

AVEVA’s new operations control software bundles now allow end customers to use all of its products

AVEVA’s response is to offer technological solutions with on-demand access. “What we are doing is we are creating these AVEVA operation control bundles, available through our AVEVA Flex plan. It is a bundle for the edge, for supervisory level and for the enterprise. We can actually go from edge to enterprise with these bundles,” according to him.

But unlike AVEVA’s previous pricing model, the AVEVA operations control software bundles are going to be priced differently. AVEVA’s previous pricing model was based on hardware and not on the end user. “This is not necessarily optimised for how the customer wants to buy. The customer wants to make sure they are seeing a strong value proposition,” says Grimes.

AVEVA is changing the pricing model of its operations software control bundles. It will now be slab-based using two parameters, including a slab-wise determination of the number of users as well as counting of the number of sites in the small, medium, large levels. “If you do the multiplication, there is the total bill,” indicates Grimes.

The company will now offer its entire operations software portfolio to a particular site at a specific price. It will not just be licenses for individual products. Within these operations control software bundles, AVEVA has multiple HMI SCADA products, and covers everything from the edge to the core and to the systems.

Another limitation from the previous pricing model was that, there were functional overlaps in the products. And since different customers used the software at different places and at different times, the per-use pricing was confusing.

Close to 85% of AVEVA’S HMI SCADA business is sold through AVEVA distributors

AVEVA’s new operations control software bundles now allow end customers to use all of its products, the way they want to use them. “And we give a bunch of Flex credits for what you are doing. So, we can manage it with our subscription database, and tie it back to the AVEVA Flex model that we had announced a year ago,” says Grimes. “This whole site centric model is going to be key for our customers, as it gives them freedom on how they want to buy.”

AVEVA Flex Subscriptions also give systems integrators access to provide a recurring expense for software licensing on a periodic basis versus the one-time perpetual licensing purchase model. This recurring license purchase allows customers to move from capital asset purchases to operating expenditures, matching budgets to requirements. Customers can increase or reduce their software licensing based on their activity levels.

“We work closely with our systems integrator partners and our main focus now is to actively expand our network,” he adds.

Vertical and horizontal value for channel

The AVEVA Partner Network allows systems integrators to engage with over 4,500 partner companies and 5,700 plus certified developers across industrial segments. It opens up opportunities for enhanced global collaborations, higher margin businesses and allows systems integrators to leverage complimentary skills from other partners and improve brand equity through certifications and endorsements.

System integrators can leverage cloud benefits through AVEVA Connect

The company recently enhanced its Partner Network for System Integrators program by providing access to a broader spectrum of the AVEVA portfolio for training and certification. The improved programme presents further opportunities for system integrators to offer increased value to their customers through application of AVEVA software.

The AVEVA System Integrator Certifications range from the entry-level Registered System Integrator up to Certified System Integrator, then at the highest level, Endorsed System Integrator. Systems integrators are classified according to this tiered system, which is based on experience with specific products, proven industry expertise, markets served and degree of desired business collaboration with AVEVA.

Industrial enterprises are responding to changed ways in which we do business in new normal

System integrators can leverage cloud benefits through AVEVA Connect, a unified industrial software cloud platform that spans the company’s entire software portfolio. It offers easy access for systems integrators to provide AVEVA products and services in the cloud.

By using AVEVA Connect, system integrators can gain benefits such as scalability, flexible pricing, high-availability, disaster-recovery, moving from infrastructure costs to operating costs, collaboration and faster response times.

Close to 85% of AVEVA’S HMI SCADA business is sold through AVEVA distributors. “That is one of the things we do not want to change,” says Grimes. “AVEVA distributors boost reach and coverage in their region, they also support customers. It does not make sense for us to go in those markets and build that kind of support and try to do something different when our distributors already have those strengths in place.” From an AVEVA partner point of view, they know what is in it for them, he adds.

AVEVA and Microsoft are committed to empowering industries to action their sustainability goals

AVEVA distributors can also benefit from the company’s AVEVA Select programme, which is designed specifically for select AVEVA distribution partners. The AVEVA Select Partner designation allows distributor partners to enable customers simplify design, optimise production, and maximise performance, to accelerate their digital transformation agendas.

Microsoft recognises AVEVA as #1 energy cross-sell partner

AVEVA was recognised as the 2021 Microsoft Energy Partner of the Year as well as was named a finalist for 2021 Microsoft Sustainability Changemaker Partner. AVEVA was chosen from a set of more than 4,400 nominations from over 100 countries with an elaborate selection process.

AVEVA and Microsoft work together to enhance customer experiences across the industrial value chain. In energy, organisations deploying AVEVA Energy Management and Performance Solutions also benefit from using Microsoft Energy Core solutions.

In the process, customers realise reductions in project implementation times of up to 60% when compared to bespoke implementations of intelligent operations – thanks to real-time, 360-degree view of the value chain, and predictive maintenance and operations. Grimes says the benefits work equally well for other sectors.

AVEVA recently announced its participation in Microsoft’s Sustainability Global Campaign